DFI production capacity status

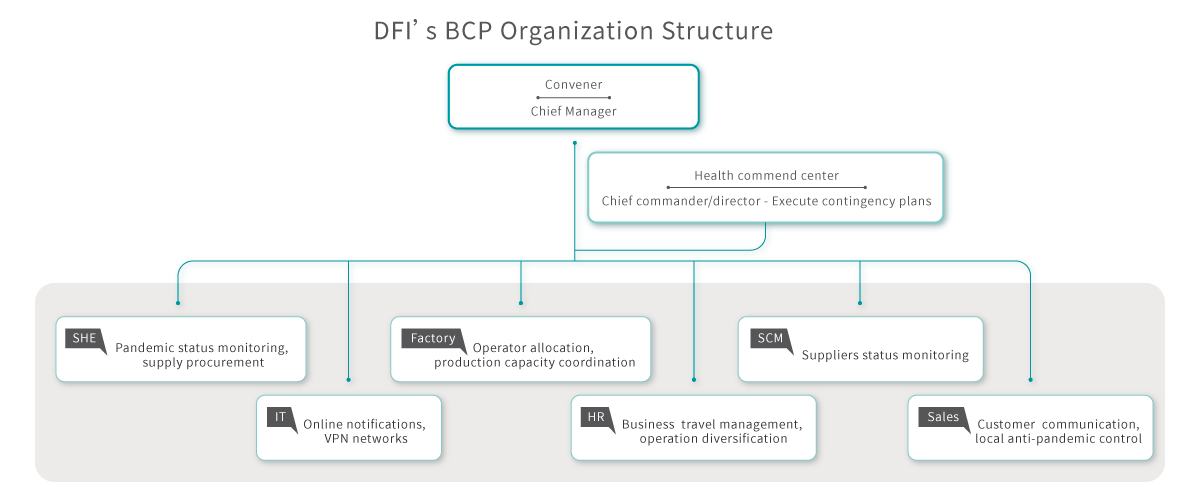

The rigorous anti-pandemic control prioritizes the safety, health, and well-being of every single employee within DFI's operation and factories. DFI's global workers, approximately 800 individuals, have been informed to suspend non-essential travels since early January. Promotion of personal hygiene and sanitary measures has been duly addressed. In the meantime, instant status reports from production and supply chain are assured to remain available through and out as long as the crisis lasts. Paired with DFI Headqurter's contingency measures, we aim to minimize the short-term adverse impacts brought by the pandemic.

Disciplines regarding personnel

- Rigorous controls over business travels — non-essential travels shall be suspended;

- Virtual conferences are strongly advised over physical ones;

- Visitors shall have their body temperatures taken and hands disinfected before entry;

- All visitors must submit a health declaration form before entry;

- Workers shall have their body temperatures taken and hands disinfected before entry;

- Everyone is mandated to wear a face mask during physical meetings

- Staff shall have face masks on along all the production lines.

Disciplines regarding operations

- Public space is disinfected on regular basis;

- Anti-pandemic measures are taken at management levels and well-publicized

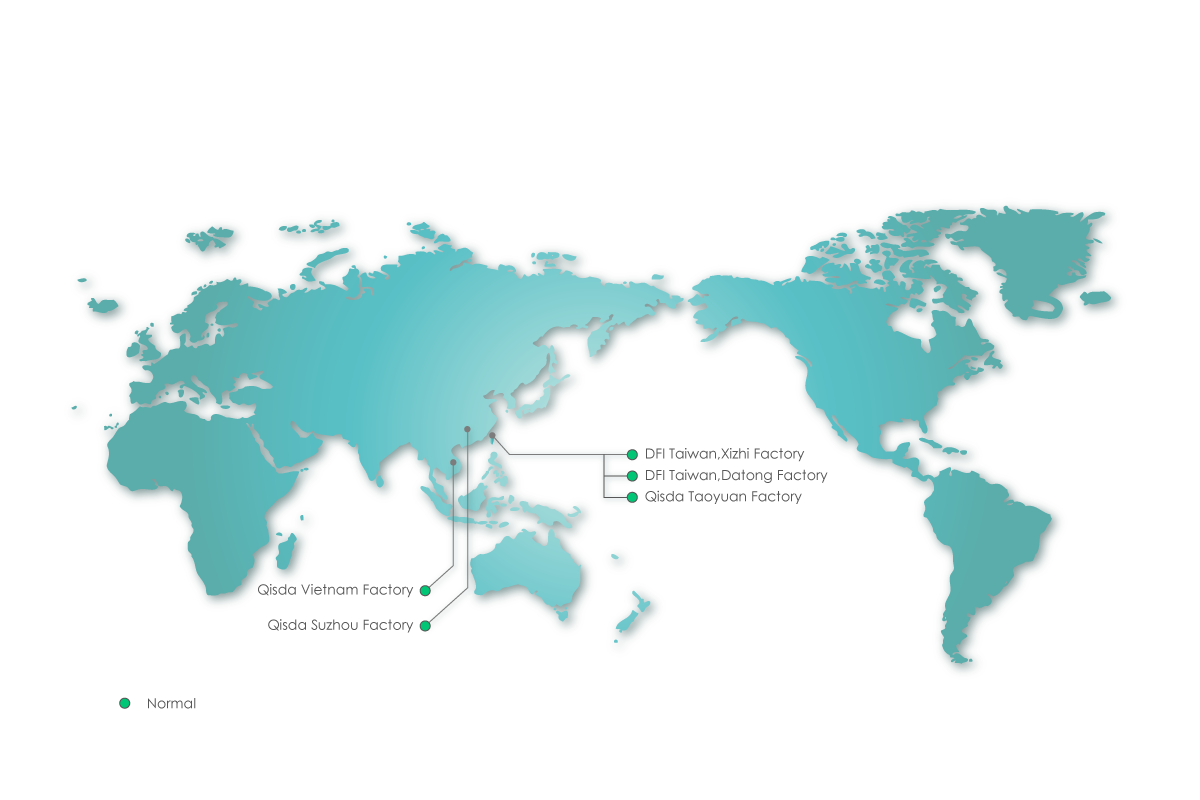

DFI's production capacity status of all factories

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)