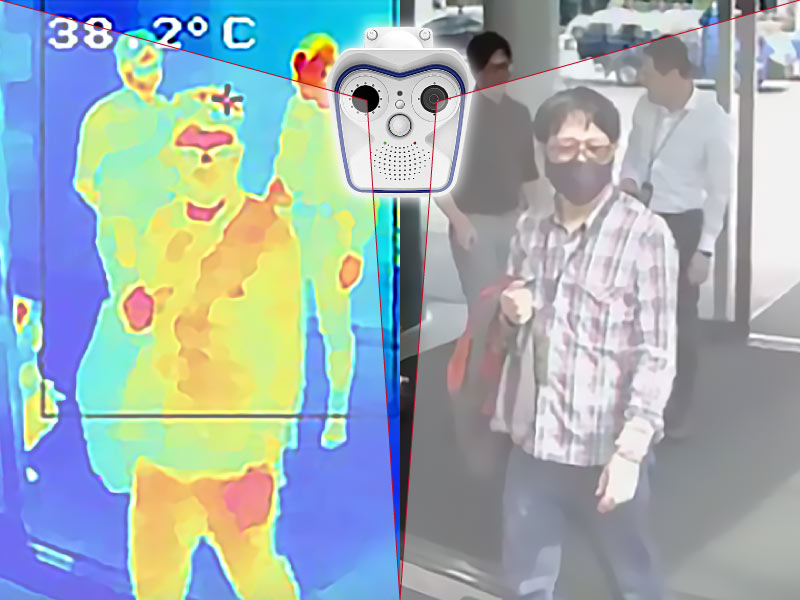

Man-power Shortage: Measuring Temp and Security Check

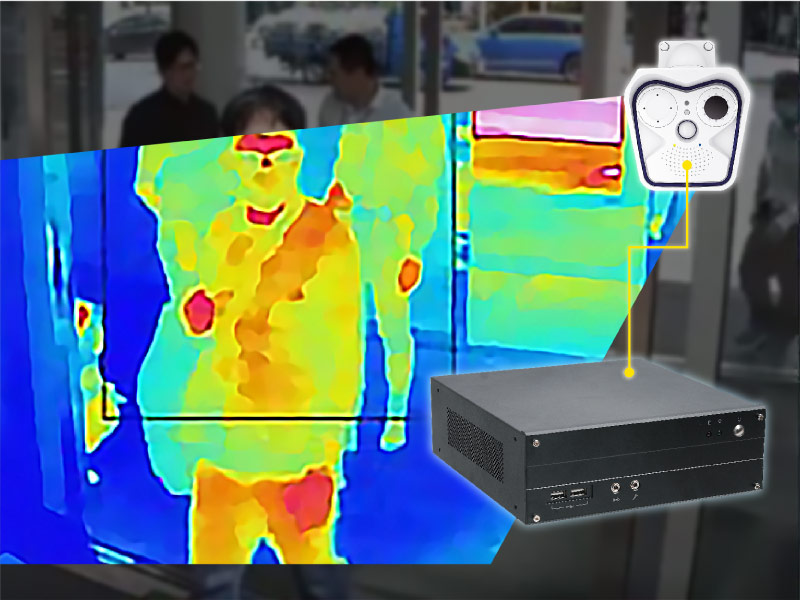

In the battles against the COVID-19 pandemic, demands of screening devices and efforts are increasing. Also, more labor has been put into monitoring body temperatures of those at public entrances. To help lift off some of the burdens, DFI recently rolled out a new smart solution — the Centralized Smart Thermal Control System for smart entrance to automatically detect massive feverish people at the same time.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)