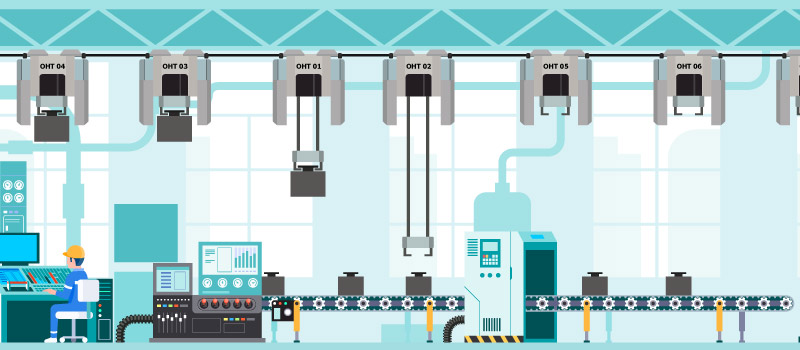

With the birth of intelligent factories, automated handling systems are increasing to reduce labor costs and handling time. The OHT (Overhead Hoist Transfer) is widely recognized as the primary transport system for next-generation fabrication plants. In the semiconductor industry, which has been in fierce competition for a long time and has rapid changes in advanced process technology, intelligent factories must also keep pace with the times to optimize existing production lines and improve production efficiency. Based on Qisda Group's long-term experience in the semiconductor industry, and the comprehensive product specifications of DFI, it assists a well-known Japanese semiconductor equipment manufacturer to obtain the most suitable control brain for OHT.

Region: Japan

Industry: Semiconductor

Application: Overhead Hoist Transfer (OHT)

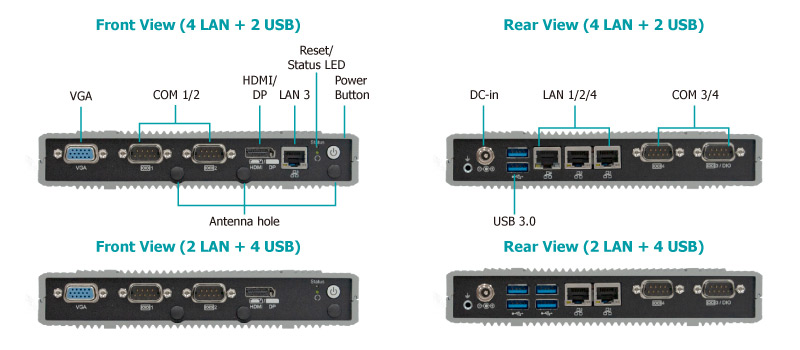

Solution: EC700-AL

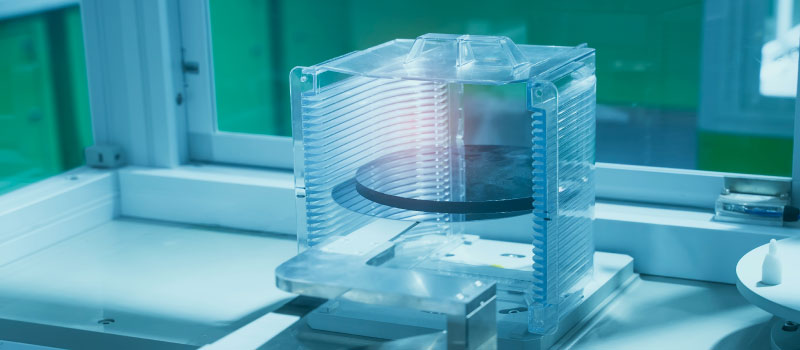

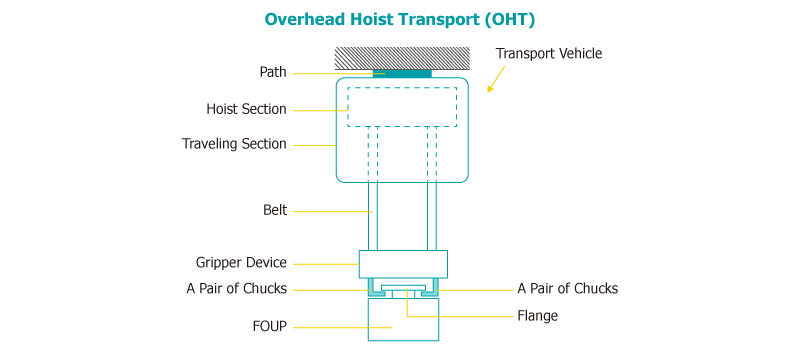

The OHT is an automated transport system that travels on the overhead track and "directly" accesses the loading port of the stocker and processes equipment by the belt-driven hoisting mechanism. The OHT can pick up front opening unified pods (FOUP) of load-port unit (LPU) for highly efficient process flow and inventory management to realize fast and stable wafer handling in each processing section without occupying the cleanroom floor space. The OHT is widely deployed in transporting 12-inch wafers in the fabrication plants, including direct tool-to-tool, tool-to-buffer, and buffer-to-tool transportation of WIP (Work in Process) carriers. In addition to being used for intra-bay transport, OHT can also be used for inter-bay and even inter-building transport.

The OHT can effectively make use of the three-dimensional space of the factory building and maximize the space utilization rate of the cleanroom without occupying the personnel aisle. In addition, predicting and analyzing the handling time through simulation can effectively shorten the waiting time for handling, move quickly, avoid scheduling problems, and realize path optimization, so that the transportation of OHT in the cleanroom can be more in line with production needs.

Qisda Group has been working in the field of robotics for many years. The initial deployment in China factory for self-use was later imported into the Taiwan factory and expanded to the outside world. Applications and customers have already covered the semiconductor industry. In addition to shipping Qisda's AGVs to major foundries, DFI has also entered the OHT market, supplying boards and barebones to OHT system integrators and chip packaging and testing plants in Taiwan to grasp the business opportunities of intelligent factories.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)