Overhead Rail-Mounted Inspection Robot for Pipe Gallery

From electric power, oil and gas, rail transit, water affairs, mining, aquaculture, ports, to metallurgy and other industries, urban underground pipe corridors, power tunnels, power distribution houses, traffic tunnels, rail transit tunnels, power plant coal trestle bridges, industrial plants, etc. are common scenarios of the pipe gallery. High pressure, electromagnetic solid, and humidity are primarily complex and in high-risk environments. Therefore, the inspection robots that run on overhead rails and move around in the pipe gallery have always been a ubiquitous demand. The ultra-thin, stable, high-reliability, and shock-resistant EC700-BT helps customers build the most trustworthy overhead rail-mounted inspection robot for pipe gallery.

Region: China

Industry: Inspection Solution

Application: Overhead Rail-Mounted Inspection Robot for Pipe Gallery

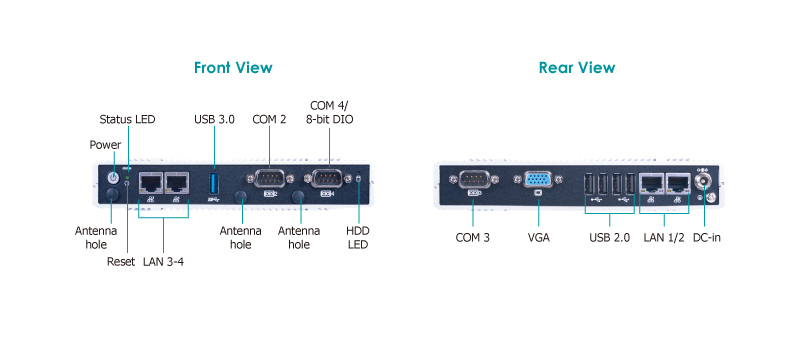

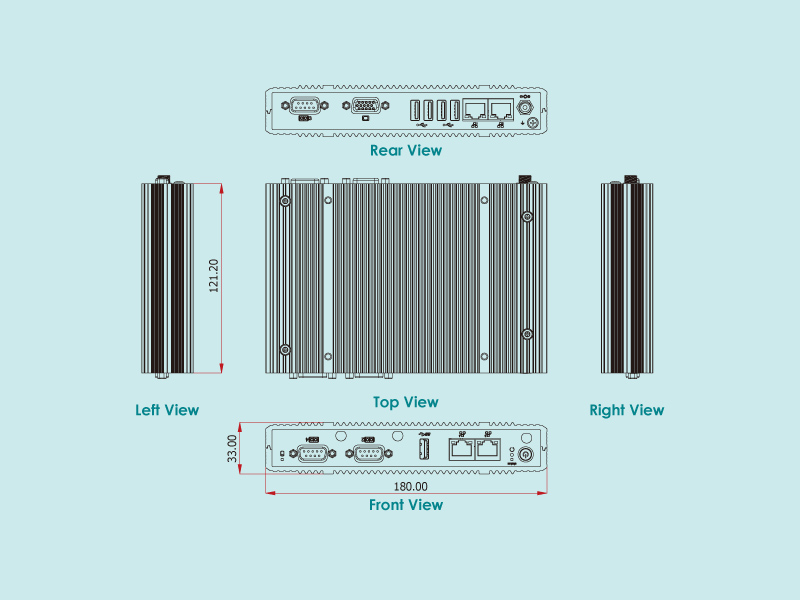

Solution: EC700-BT

Scenarios such as urban underground pipe corridors, power tunnels, power distribution rooms, traffic tunnels, rail transit tunnels, power plant coal trestle bridges, industrial plant areas, etc., have never been suitable for on-site human operations, especially hazardous work such as detecting corrosion of cooling water loop pipes in nuclear power plants. Therefore, an inspection robot that moves around on a pre-laid track and has a robotic lifting arms mechanism has become essential equipment in this type of field.

A Chinese company founded in 2011, whose technology is based on multi-dimensional motion control and artificial intelligence algorithms, has developed a series of solar panel cleaning robots, wheeled inspection robots, track inspection robots, and firefighting robots that work by throwing dry powder to extinguish fires. These robots also serve many industries such as electric power, oil and gas, rail transit, water affairs, mining, aquaculture, ports, and metallurgy, and provides reliable and economical solutions with intelligent inspection solutions for these industries.

Its inspection robots move on pre-laid lightweight tracks to inspect designated areas and operate reliably in complex environments such as high pressure, electromagnetic solid, and humidity. The robot carries two sets of 360° webcams, ambient gas sensors, partial discharge sensors, and other equipment to obtain multi-dimensional data from the inspection area, then using AI intelligent recognition algorithms to perform meter readings, defect diagnosis, and analysis with thermal imaging. In addition, the centralized robot control and management platform can connect multiple robots to perform intelligent data analysis, along with early warning of faults and defects, and intelligent unmanned inspection.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)